Determining the appropriate rotor speed for a vertical filter cake crusher will depend on several factors, including the type and size of the filter cakes, the material being filtered, and the desired output size.

Here are some steps to help determine the appropriate rotor speed:

Consult the manufacturer’s guidelines: The manufacturer of the vertical filter cake crusher should provide guidelines and recommendations for the appropriate rotor speed for different applications. These guidelines will vary depending on the specific model and design of the equipment.

Consider the material being filtered: The material being filtered can affect the appropriate rotor speed. Harder or denser materials may require a higher rotor speed to effectively crush the filter cakes, while softer or more delicate materials may require a lower rotor speed to avoid damaging the material.

Determine the desired output size: The desired output size can also affect the appropriate rotor speed. Higher rotor speeds can produce smaller output sizes, while lower rotor speeds may produce larger output sizes.

Conduct trials: Conducting trials with different rotor speeds can help to determine the most effective rotor speed for your specific application. Start with a lower rotor speed and gradually increase it until the desired output size is achieved.

Monitor the process: Once the appropriate rotor speed has been determined, it’s important to monitor the process and make adjustments as needed to ensure optimal performance.

Overall, determining the appropriate rotor speed for a vertical filter cake crusher will require careful consideration of several factors and may require some trial and error. Consulting with a filtration expert or equipment supplier can also provide valuable guidance and recommendations.

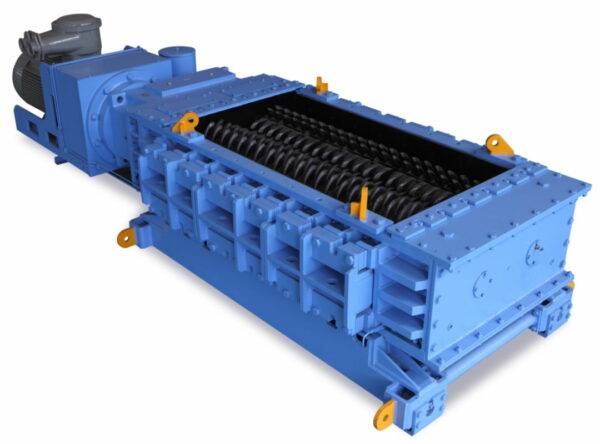

Vertical filter cake crusher

A vertical filter cake crusher is a type of equipment used in the filtration process to crush and reduce the size of filter cakes. Filter cakes are formed when solids are separated from liquids, and they can accumulate on filter plates or cloths during the filtration process.

The vertical filter cake crusher typically consists of a vertical shaft with a rotor at the bottom, which rotates cake breaker at high speeds to crush and reduce the size of the filter cake. The filter cake is fed into the crusher through a hopper, and the crushed material is discharged through a chute or conveyor.

This type of equipment is commonly used in industries such as wastewater treatment, chemical processing, and mining. By reducing the size of filter cakes, the vertical filter cake crusher can improve the efficiency of the filtration process and reduce the amount of waste generated.

It’s worth noting that the specific design and features of a vertical filter cake crusher can vary depending on the application and the specific needs of the user. Some models may include additional features such as adjustable rotor speed, automatic cleaning systems, and safety guards. It’s important to consult with a filtration expert or equipment supplier to determine the best type of vertical filter cake crusher for your specific needs.