The cost of PTFE and FEP can vary widely depending on a number of factors, including the specific application, the quantity needed, and the supplier. However, in general, PTFE is typically more expensive than FEP.

One reason for the higher cost of PTFE is that it is a more complex material to manufacture than FEP. PTFE requires a longer processing time and more specialized equipment than FEP, which contributes to its higher cost.

Another factor that can impact the cost of PTFE and FEP is the specific grade of the material. Both PTFE and FEP come in a range of grades with different performance characteristics, and higher-grade materials may be more expensive than lower-grade materials.

Overall, the cost difference between PTFE and FEP may be relatively small for some applications, while it may be more significant for others. When choosing between PTFE and FEP, it is important to consider the specific requirements of the application and to select the material that provides the best combination of performance and cost-effectiveness. Consulting with a material supplier or expert can be helpful in determining the best material for the job at hand.

How do the performance characteristics of PTFE and FEP compare?

PTFE and FEP have some similarities in performance characteristics, but they also have some differences that make them better suited for specific applications. Here are some key performance characteristics of each material:

PTFE:

High chemical resistance: PTFE is highly resistant to a wide range of chemicals, including acids, bases, and solvents.

Non-stick properties: PTFE has a very low coefficient of friction, China PTFE FEP supplier which makes it ideal for non-stick coatings.

High temperature resistance: PTFE can withstand high temperatures up to 260°C (500°F).

Electrical insulation: PTFE is an excellent electrical insulator, making it suitable for use in electrical components and insulation.

FEP:

Flexibility: FEP is more flexible than PTFE, which makes it easier to process and mold.

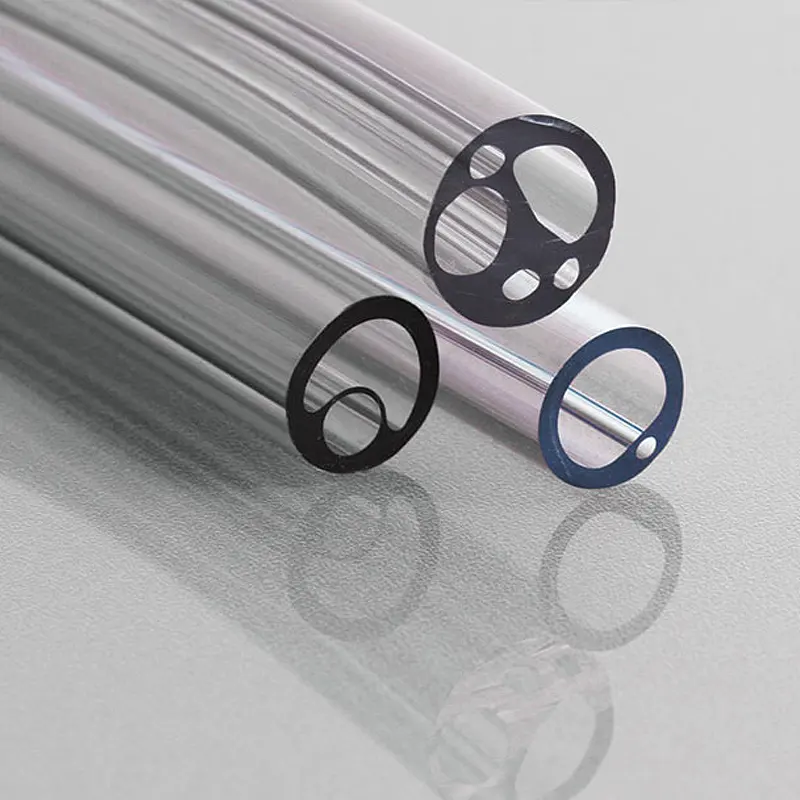

Transparency: FEP is transparent, which makes it suitable for applications where visibility is important.

Chemical resistance: FEP is highly resistant to many chemicals, although it may not be as resistant as PTFE in some cases.

Low temperature resistance: FEP can withstand low temperatures down to -80°C (-112°F).

Electrical insulation: FEP is also an excellent electrical insulator, although not quite as good as PTFE.

Overall, both PTFE and FEP are high-performance fluoropolymer materials that offer excellent chemical resistance and electrical insulation properties. PTFE is better suited for high-temperature applications and non-stick coatings, while FEP is more flexible and transparent, making it a good choice for medical tubing and wire coatings. When selecting between PTFE and FEP, it is important to consider the specific performance characteristics required for the application and to choose the material that best meets those requirements.