Spacer fabric and interlock fabric are both types of technical textiles used in various applications, while viscose is a semi-synthetic fiber derived from natural sources such as wood pulp.

When comparing their environmental impact, several factors must be considered:

- Raw Material Source:

- Spacer fabric and interlock fabric are typically made from synthetic fibers such as polyester or nylon, which are derived from petrochemicals. The production of these synthetic fibers involves the extraction and processing of fossil fuels, which can have significant environmental impacts, including greenhouse gas emissions, habitat destruction, and air and water pollution.

- Viscose, on the other hand, is derived from renewable natural sources such as wood pulp or bamboo. While the production of viscose involves deforestation and chemical processing, efforts are being made to improve the sustainability of viscose production through responsible forestry practices and closed-loop manufacturing processes.

- Manufacturing Process:

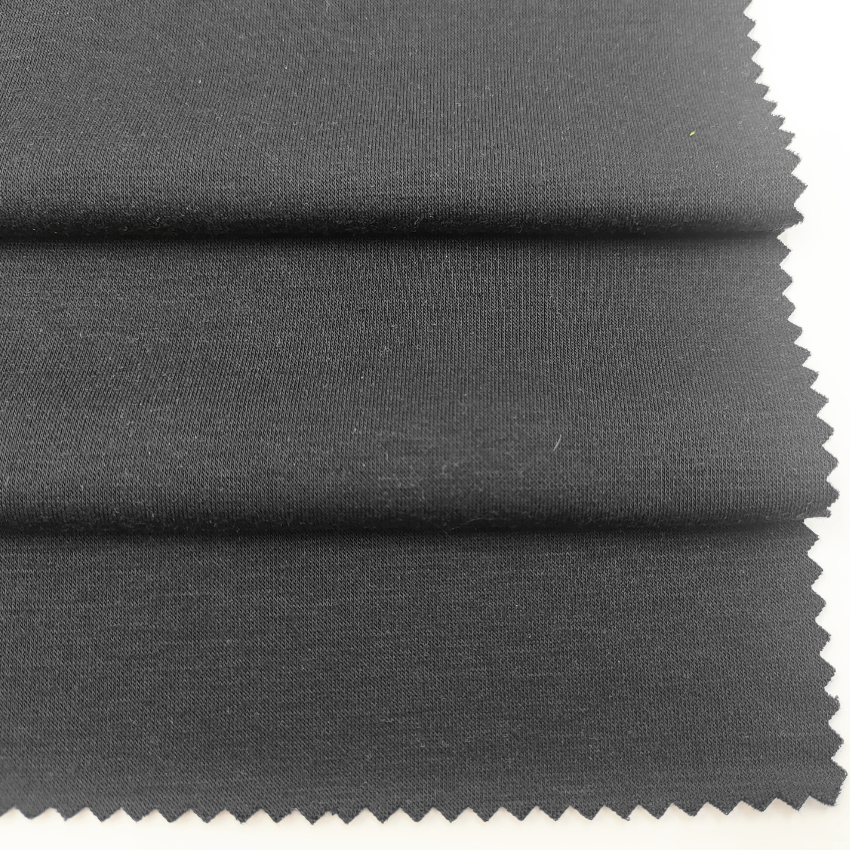

- The manufacturing process of spacer fabric and interlock fabric involves weaving or knitting synthetic fibers into a three-dimensional structure. This process requires energy-intensive machinery and chemicals for dyeing and finishing, which can contribute to environmental pollution and resource depletion.

- Viscose production also requires significant energy and water usage, as well as the use of chemicals such as caustic soda and sulfuric acid for fiber extraction and processing. However, advancements in closed-loop manufacturing technologies have enabled some viscose producers to recycle and reuse chemicals, reducing environmental impact.

- Durability and Longevity:

- Spacer fabric and interlock fabric are known for their durability and resilience, which can contribute to longer product lifespans and reduced need for replacement. However, since they are made from synthetic fibers, they are not biodegradable and may contribute to microplastic pollution at the end of their lifecycle.

- Viscose garments, China Spacer Fabric Interlock Fabric factory while less durable than synthetic fabrics, are biodegradable and can break down naturally over time. However, the environmental impact of viscose production largely depends on the sourcing of raw materials and the implementation of sustainable manufacturing practices.

- End-of-Life Disposal:

- At the end of their lifecycle, spacer fabric and interlock fabric may end up in landfills, where they can take hundreds of years to decompose. Alternatively, some synthetic textiles can be recycled into new products, reducing the demand for virgin materials.

- Viscose garments can biodegrade under certain conditions, such as composting or anaerobic digestion, reducing their environmental impact compared to synthetic fibers. However, challenges remain in ensuring proper disposal and recycling of viscose textiles.

In conclusion, while spacer fabric and interlock fabric offer durability and performance benefits, they are typically derived from non-renewable resources and may have significant environmental impacts throughout their lifecycle. Viscose, although derived from natural sources, also has environmental challenges associated with its production process. Efforts to improve the sustainability of textile production, such as using recycled fibers, implementing closed-loop manufacturing systems, and promoting circular economy initiatives, are crucial for reducing the environmental footprint of textile materials.